+86-371-64599000

+86-371-64599000

Products List

Hot Products

Silicon Carbide Rod

Silicon Carbide (SiC) is a remarkable ceramic material known for its exceptional properties, making it a preferred choice in various industrial applications. SiC rods, in particular, are widely used due to their high thermal conductivity, wear resistance, and ability to withstand extreme temperatures. In this article, we will delve into the features, technical data, and applications of SiC rods, providing you with a comprehensive understanding of this versatile material.

Silicon Carbide is a lightweight ceramic material that boasts high strength properties comparable to diamond. It is renowned for its excellent thermal conductivity, low thermal expansion, and resistance to corrosion from acids. These properties make SiC an ideal material for applications that require good erosion and abrasive resistance.

SiC rods offer a range of features that make them indispensable in various industries:

Here is a detailed look at the technical specifications of SiC rods:

| Properties | Units | SiC Material |

|---|---|---|

| Chemical composition (SiC%) | % | 89 - 99 |

| Bulk Density | g/cm3 | 2.75 - 3.01 |

| Apparent Porosity | % | 0.1 - 14 |

| M.O.R. @20℃ | MPa | 50 - 260 |

| M.O.R. @1300℃ | MPa | 58 - 280 |

| C.T.E. @20℃-1000℃ | 10-6K-1 | 4.2 - 4.8 |

| C.C.S | MPa | 90 - 900 |

| Max Working Temperature | ℃ | 1300 - 1650 |

SiC rods are used in a variety of industries due to their exceptional properties. Some of the key applications include:

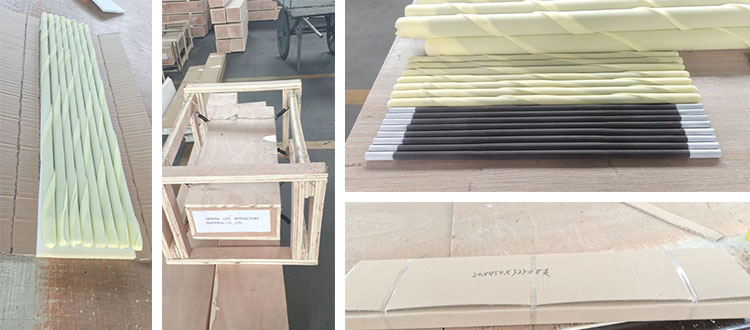

Our SiC rods are carefully packaged to ensure they reach you in perfect condition. Here are the details of our packaging and shipping process:

We offer professional car transport to various ports in China, followed by shipping with a professional shipping company. Both FOB and CIF options are available, ensuring flexible and competitive sea freight with short transit times.

Silicon Carbide rods are ideal for high-temperature applications due to their excellent thermal conductivity, low thermal expansion, and ability to maintain structural integrity at extreme temperatures.

Yes, Silicon Carbide rods are highly resistant to corrosion from acids, making them suitable for use in corrosive environments.

Industries such as sanitary ware, glass panel manufacturing, and heat exchangers benefit significantly from the use of Silicon Carbide rods due to their durability and thermal properties.

Silicon Carbide rods are packaged in sturdy wooden boxes with anti-collision protection, ensuring they arrive safely at their destination.

+86-371-64599000

+86-371-64599000 +86-371-64599000

+86-371-64599000 sale@literefractory.com

sale@literefractory.com