Clay insulating refractory brick

made from high purity fire clay, by adding combustible, gas evolution method, or foam method.Fireclay insulating brick is a kind of porous material.

►Features:

►Features:

1.Good heat insulating effect and energy-efficient

2.Good thermal shock stability.

3.Corrosion and erosion resistance

4.Long service life

Technical parameters:

|

Item |

0. 6 |

0.8 |

1.0 |

|

Al2O3(%) |

38-40 |

38-40 |

38-40 |

|

Fe2O3 (%) |

4% |

4% |

4% |

|

SiO2 |

55 |

55 |

55 |

|

B.D (g/cm3) |

0.6 |

0.8 |

1.0 |

|

A.P % |

70 |

60 |

55 |

|

C.C.S(Mpa) |

2.0 |

2.5 |

3.0 |

|

R.L.C(%)℃ X 12H ≤ |

1300℃ -0.5 |

1350℃ -0.5 |

1350℃ -0.9 |

|

Thermal Conductivity(W/m.k)(1000℃ ) |

0.33 |

0.60 |

0.45 |

►Application:

Mainly used in various industrial kilns furnace for insulating layer materials which do not contact with the melten material and have no corrosive gas effect.

►Delivery

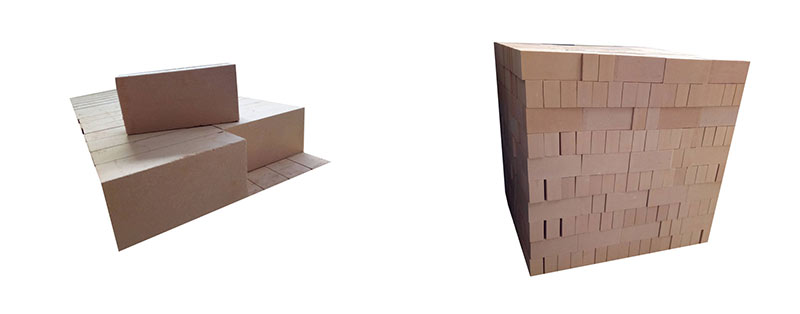

Package Informations:

1. Packed in a 100cm*100cm fumigated wooden pallet with a waterproof plastic film cover, and tightened with plastic bandages.

2. We can also pack the goods according to your requirements.

Shipping:

1. FEDEX/DHL/UPS/TNT for samples.

2. By Sea for batch goods.

3. Customers specifying freight forwarders or negotiable shipping methods!

4. Delivery Time:3 days for common shape samples;15 days for special shape samples.Within 30 days for batch goods.

+86-371-64599000

+86-371-64599000 +86-371-64599000

+86-371-64599000 sale@literefractory.com

sale@literefractory.com