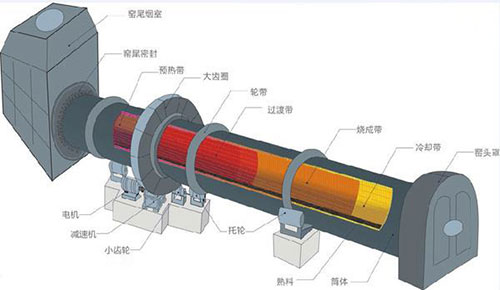

Cement rotary kilns are often called the world's largest rotary equipment.Their range in diameter is from 10 feet to 20 feet, often hundreds of feet length.When the kiln rotates on its roller, the material is transported due to the low and gradual gradient of the kiln.After the material enters the kiln, the temperature is in the hundreds of degrees Celsius. When the material arrives near the nozzle, it is heated to 1,450 degrees Celsius.Once the material reaches 1450c (called "clinker"), it is quickly cooled to quench the material, providing a high quality product.

High alumina brick belongs to aluminous silica , contain more than 45% Al2O3 refractory products. Lite can offer a wide range of high alumina bricks - from ultra-high-temperature products in the entry area to the export area of the kiln.The main feature of our products is their high refractoriness,resistance to flaking, impact and abrasion.

Magnesia chrome bricks are also used in rotary kilns. It is mainly composed of basic oxides and are used for high temperature applications.It is also known for its strong resistance to corrosion by chemical base residues, solid or liquid oxides, dust and smoke.

+86-371-64599000

+86-371-64599000 +86-371-64599000

+86-371-64599000 sale@literefractory.com

sale@literefractory.com